PLC Control Automatic Floor Deck Roll Forming Machine Roof Tile

Machine Hydraulic Cut

1. Description of floor deck roll forming machine:

Floor deck is produced by galvanized sheet rolling to shape. The

cross-sections including V-shape, U-shape, Trapezoid-shape and

Wave-shape. It mainly used as the permanent shuttering. It is

widely used for the multiple layers steel structure constructions,

such as exhibition halls, steel structure plants, warehouses, steel

structure buildings, Airports, Railway stations, Gymnasia, Concert

halls, Theaters,Supermarkets, Logistics centers, High-rise steel

structure building, etc.

2. Technical details of floor deck roll forming machine:

| Suitable material | PPGI/PPGL/GI/Aluminium |

| Machine Sizes | 10500mm×1400mm×1500mm |

| Main motor power | 5.5KW with Cycloidal reducer |

| Hydraulic station power | 4KW |

| Hydraulic oil | 36# |

| Thickness of material | 0.3mm~0.8mm |

| Diameter of principal axis | Φ70mm |

| Material expand width | 1200mm |

| Electric tension | 380V 3phase 50HZ~60HZ |

| Material of roller | High grade 45# forged steel plated with hard chrome plating |

| Rolling galvanization thickness | 0.05mm |

| Processing speed | 12-15m/min |

| Processing precision within | 10m+/-1.00mm |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Kind of drive | 1 inch chain link bearing model 6210 |

| Roller station | 18 Steps / 18 Steps |

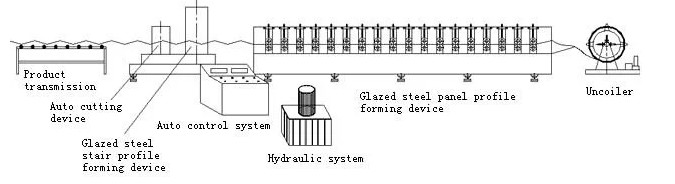

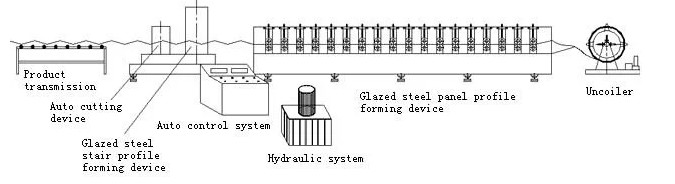

3. Floor deck roll forming machine flow chart:

Uncoiler --- Feeding --- Pre-cutting --- Roll Forming --- Post

Cutting --- Auto Stacker

4. After Sale Service

A. Foreign debugging

We will arrange our professional engineers to help you install and

debug the machines well. Buyer should pay $100for each engineer

every day and should be responsible for transportation (including

round-trip ticket), insurance, and suitable accommodation.

B. Guarantee period

1.The warranty will be maintenance, maintain in the guarantee

period of 18 months starting from delivery. Because of the quality

of equipment during guarantee period, we will provide the parts

free of charges, which is in the conditions of correct operation.

(Natural disasters or factors which can’t forced by human are

excluded).

2.If the equipment are out of work in the guarantee period, the

buyer needs our repairman to come to buyer’s factory, the buyer

should be responsible for the tickets(including round-trip ticket),

the fee of transportation to the buyer’s factory andaccommodation.

Required to change spare parts, the buyer should afford the freight

fee and we don’t ask extra fee.

C. Training

During installation and adjustment of the equipment, our engineers

shall provide the training to buyer’s personnel request to operate

and maintain the equipment. Including foundation construction,

electrical works, hydraulic oil, safe operation and non-standard

safety items, testing material and etc.

D. Lifetime services

Lifetime services to every customer.

5. Advantages:

1.Good quality: We have a professional designer and experienced

engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of

our machines.

3.Guarantee period: within one year since the date of finishing

commissioning. The guarantee covers all the electric, mechanic and

hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling

systerm.

5.Elegant apperance:Protect the machine from rust and the painted

colour can be customized

6.Reasonable price:We offer the best price in our industry.

6. Picture